The Huston Crafted Series brings you a little closer to the world of textile design and making as we highlight the hidden details that go into producing our collection of premium cloth, running the creative gamut from knits to woven goods. At Huston, we restore and empower a heritage of fiber craft through a truly artisan American textile making experience. In this first edition of the series, we look through a few of our favorite custom denim projects, and some of the process it takes to create at our domestic mill. Lets dive in at our denim fabric and process favorites – our 12oz Double Slub, a 14oz Botanical Indigo and a 10oz Natural denim – lets explore !

Denim Weaving Process -

As a denim is brought to life, the design process of material selection and machinery selection is paramount. When we consider a denim project on our looms – these are the key points to consider for a beautiful product without too much waste.

– Raw Material, Warp and weft yarn specifications including TPI (twist per inch), size, color, weight, end pattern and strength/application characteristics. Once we have a sample yarn and prototyped construction of a test swatch (before larger productions), we can further tweak the variables.

Raw Materials and Designing an End Denim Product from the Field

Cotton comes in many shapes, sizes and colors! A variety of cotton genetics are grown domestically, from California to West Texas, and beyond. We continually work with our coalition partners in third party domestic fields of expertise – from regional farmers to upstream manufacturing facilities – to produce fine domestic products, and processes for our products with our supply chain partners.

What is Denim?

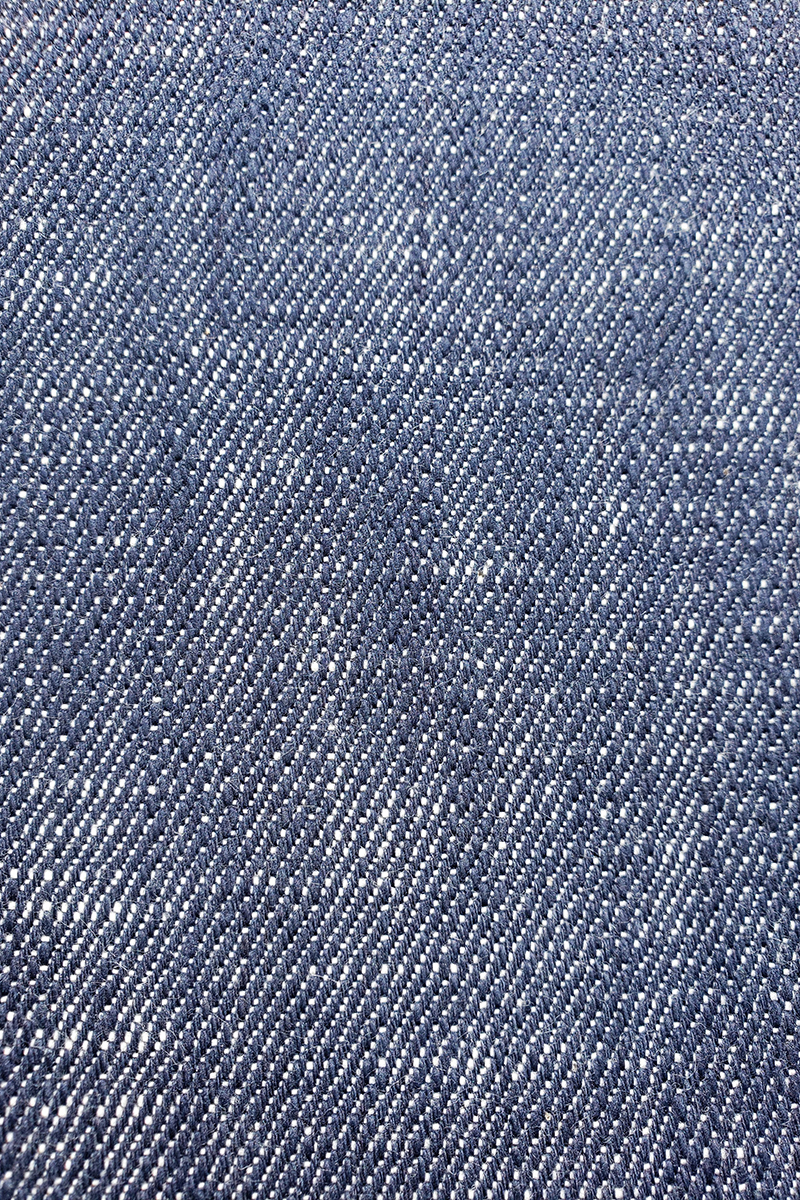

Denim is a sturdy cotton warp-faced textile in which the weft passes under two or more warp threads. This twill weaving produces a diagonal ribbing that distinguishes it from canvas, and often makes it a stronger construction for utilitarian toughness. The main difference between denim and canvas is the weave construction. Canvas is made with a simple plain weave pattern of “over one, under one”. (*Using two yarns in the over under instead of one, but it is still a plain weave, is often referred to as ‘double fill’).

Characteristics of denim Twill fabrics are made by going over one yarn and under two yarns or even under three yarns. The weave is shifted over in each row creating a diagonal line in the pattern. The diagonal line makes a twill easy to identify

Denim is available in a range of colors, but the most common denim is indigo denim in which the warp thread is dyed while the weft thread is left white. As a result of the warp-faced twill weaving, one side of the textile is dominated by the blue warp threads and the other side is dominated by the white weft threads. Modern day denims fabricated from this cloth are thus predominantly white on the inside.

Body PIC-denim yarns/color and setup to machine convos ahead

Our historical denims are made on traditional shuttle looms which typically produces a bolt about 35 inches (760 mm) wide. We do have several size looms to accommodate up to 58’ finished widths.

Body PIC ; MACHINE/S most used in our denim’s weaving stage shown (Draper X3/XD)

Body VID : MACHINE/S most used in our denim’s weaving stage shown (Draper X3/XD)

SELVAGE or selvedge came from ‘SELF-EDGE’ is also referred to as ‘Redline.’ Selvage is the narrow tightly woven band on either edge of the denim fabric, parallel to the warp. A selvage end prevents the edge of the denim from unraveling. In some fabrics selvages are closed, whereas on larger modern weaving machines, the weft yarn is cut on every pick, creating what is called a ‘fringe’ selvage.

Although not always the case, shuttle-loom-woven denim is typically recognizable by density, and by its selvedge, the edge of a fabric created as a continuous cross-yarn (the weft) reverses direction at the edge side of the shuttle loom. The selvedge is traditionally accentuated with warp threads of one or more contrasting colors, which can serve as an identifying mark.

Body PIC - Selvedge – ticker ids (even if on Chambray/canvas, next to each other to show differencens

Although quality denim can be made on many looms, selvedge denim has come to be associated with premium products since final production that showcases the selvedge demands artisan care, and price points.

Denim fabric thickness can vary with a yard of fabric weighing anywhere from 9 to 32 oz, with 9 to 14 oz being typical range used in consumer apparel and accessory goods. Our looms are capable of heavy denims, however not ‘bull denims’ which usually push past 15oz fabric weight constructions and require more specialized machinery.

Woven Materials Displayed include :

FABRIC – 100% American-Made Botanical Indigo Denim

SOURCING – American upland cotton, yarn spun and skein dyed in North Carolina

PROCESS – A super soft, long-lasting denim fabric made from 100% ring spun cotton; woven on our vintage Draper X3 loom

DYES – 100% botanically dyed organic cotton warp, natural organic cotton weft

DETAILS – Weight: 14oz | Width: 33" | Right Hand 3/1 Twill

FABRIC – 100% American-Made Double Slub Selvedge Denim

SOURCING – American upland cotton sourced from West Texas, yarn spun and dyed in North Carolina

PROCESS – A super long-lasting and soft slub denim made from 100% ring spun cotton; woven on our vintage Draper X3 loom

DYES – Blue sulfur dyed slub warp for a mineral dye quality that stays richer longer, with natural slub weft

DETAILS – Weight 12oz | Width: 28" | Right Hand 3/1 Twill

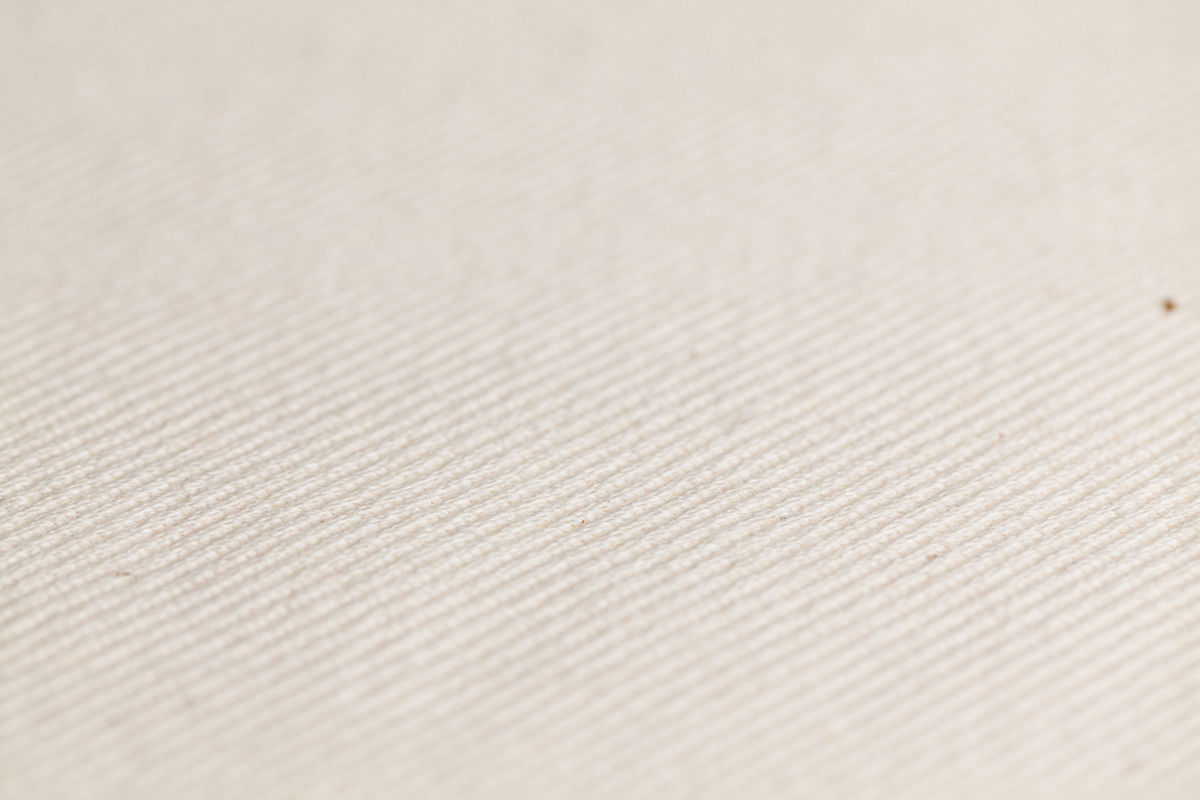

FABRIC – 100% American-Made Natural Denim

SOURCING – American West Texas Organic cotton sourced, yarn spun and dyed in North Carolina

PROCESS – A pairing of natural organic cotton weft with a natural organic cotton warp; woven on our vintage Draper X3 loom

DYES – Natural warp and natural weft

DETAILS – Weight: 10oz | Width: 45" | Left Hand 3/1 Twill

If you’re looking for a little inspiration or simply want to expand your fabric knowledge, check back often as we are adding expanding content monthly. We’d also love to hear your feedback with what you’d like us to produce and share next – please send us an email or give us a call to talk about your project!

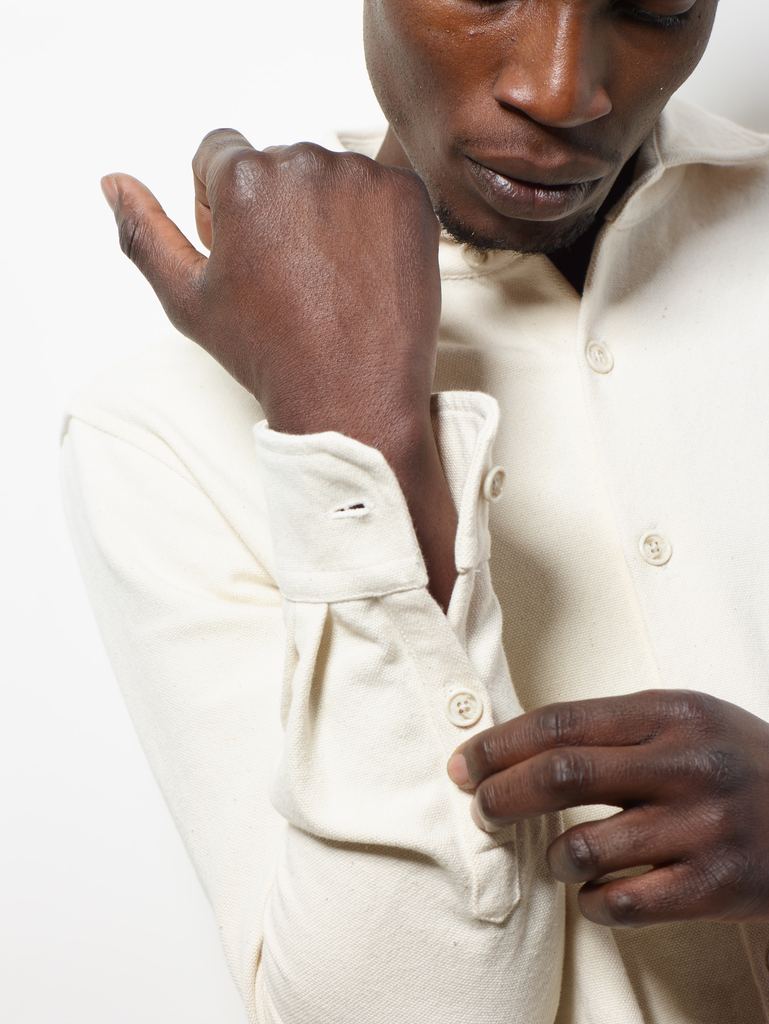

Kali Made Garments is making a name for itself in the California apparel scene. Founded by Bay Area native, Victor Kali, this locally-made bespoke men's brand prides itself on small batch, luxury staples for the conscious clothing wearer. We sat down with Victor, at his downtown Oakland home, to tap into his inspirations, creative design rhythm and to learn more about his love affair with the Bay.

Your Full Name:

Victor Manoa Kali

Your favorite food:

Burritos

Where were you raised?

South San Francisco and Millbrae, to be exact.

Something interesting that we might not know about you.

I’m a huge basketball fan and have been playing and watching as long as I can remember. My first job was actually working at a kids basketball camp, which used the game to not just teach athletic skills, but also how to be a complete and healthy person with respect for the world around you and all the people in it. I also work pretty closely with the local artist community in Oakland, and like helping out with shows, events etc to support the artists on a personal and ground level so they can continue to pursue their dreams like I do mine.

What prompted you to start a men’s clothing line?

I was always interested in clothing and it’s ability to inspire and affect people’s feelings about their surroundings. Growing up, my garments were a way for me to personally feel more confident and secure. After learning the ropes of the corporate fashion system, I decided to start my own brand more in line with my values. I think timeless pieces that age gracefully and mature with a person are the most valuable; they allow for confidence to become a more internal, natural development rather than relying on the need for outside gratification that is all to prevalent in our current society.

Tell us more behind the “Kali Made” name and why you decide to produce locally in the Bay.

Well, I’m not the most creative person when it comes to marketing and branding, so I just decided to use my own name for the brand! Kali is obviously my last name, and I make garments, but I also want the brand to represent the lifestyle and culture I grew up in in the Bay Area. California is a very inclusionary and unique place - Kali Made is a representation of my pride for our special place in the world. I decided to produce in the Bay for a few reasons - I have a pretty free flowing creative process, so it really helps to be close to the production facilities to make sure everything gets made to the highest level of quality, and I can iterate and make decisions with more freedom. I also wanted to keep my investments in the community I live in. And from an environmental standpoint, keeping the production pipeline as local as possible greatly reduces my reliance on traditional shipping and production processes which contribute to “soft” consumption of resources through the pipeline.

Who do you design your clothing for?

I hope my garments appeal to a customer who is less interested in being fashionable and more inspired by presenting a conscience and considered persona. I don’t make clothes to stand out, really. My ideal customer is quietly confident in themselves and what they stand for, and isn’t afraid to live their own best life, whatever that means.

You integrate elements of sustainability into your work. Can you tell us more about that and why it is important to you?

The move toward sustainability isn’t really a choice we have any more. It’s an almost moral question we have to reckon with as a civilization built on mass consumption, that we have to live and create in ways that are better for our internal and external environment. I’m not mad at how we have developed to gain gratification from our current consumption patterns, but we have to figure out how to be a more responsible and thoughtful society overall. I definitely don’t have all the answers, but I hope to at least be asking the right questions.

What was your first encounter with the Huston Textile Co.?

A few years ago I saw on social media that a small local shirt maker had made a piece with some local textiles. I’m a bit of a fabric and production nerd, so this made me really excited. I looked up Huston Textile and gave Ryan a call. The next week I drove out to meet him and see his shuttle loom, and it was awesome! I felt like I’d met a kindred soul - until then I didn’t really know anybody else passionate about heritage quality textiles, especially in the US. The fabric itself is amazing, and seeing how him and Kat have grown this local fabric community into a little family is super inspiring.

What is your favorite piece of clothing that you’ve developed?

Well, I really like my Universal Track Jacket, as an everyday wearable heritage piece that works on tons of different people, styles, body types, etc. It was nice to put my own little luxurious twist on a pretty classic silhouette. I love seeing what people react to what fabrics and combinations - it’s all about what I hope makes people happy and confident in themselves. The fact that people from all walks of life have reacted positively to this style makes me really happy and makes me feel like I’m helping grow a tight little community in its own right.

How do you choose the textiles you work with?

Quality and a good hand feel are my topmost priority when choosing textiles. I want my garments to have a very tactile quality to them, so even if you don’t see them per se, when you are wearing them you can definitely feel them. I tend to gravitate toward heavy soft cottons and finer wools. Being able to layer your pieces is a huge part of my style and life in the Bay Area, so versatility is kind of ingrained in my psyche at this point. I also like the idea of mixing and matching fabrics and styles in unconventional ways, like using an indigo dyed Italian denim for a sport coat, or a fine tuxedo style wool crepe for a more casual track jacket.

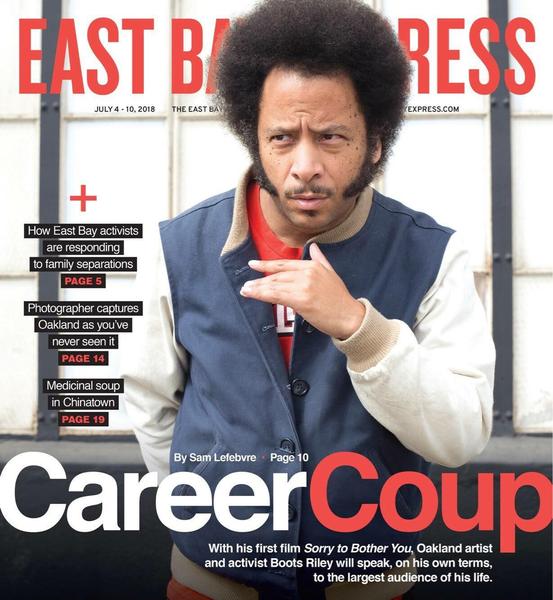

Your bespoke clothing has influenced many people in the Bay Area. Have you dressed anyone we would know of?

My friend Boots Riley is an activist, artist, and now successful film director who has really been rocking my stuff lately! He made this wild social commentary (and hilarious) film “Sorry To Bother You”. We were already friends from the Oakland scene, and seeing his latest successes in a new field have been amazing. Also my buddy Nate from the band Tune Yards likes to rock his Kali Made Garments jacket on tour - I’m glad my garments get to see the world!

What does the future of Kali Made look like?

Just keep moving forward, one collection at a time! Ideally I would love to establish a more consistent direct sales business, so I can keep working with Huston and my local factories and exploring new styles that keep me excited as a designer. I’ve got a few new tricks coming down the pipeline - I think the next step for Kali Made Garments is to start expanding my own horizons and creating pieces that are a bit more unique but still in line with my core concepts for the brand.

Where can we find your collection?

Online at kalimade.com has the complete assortment. I have limited collections in a few boutiques in the Bay Area, like Viscera boutique in Oakland and Hapertas and Co. in San Jose.

Anything else you’d like to add?

Just want to say thank you to everyone I’ve had the pleasure of working with or supported Kali Made Garments in any way, from picking up a piece or just showing love for new styles. I have to remind myself sometimes that I started the brand to bring my little piece of beauty and joy into the world, and every day that I get to keep Kali Made Garments moving forward is an immense honor and pleasure.

images by mrkrbnsk@gmail, @urbanm11

Imagine if you wore clothing that had a beneficial impact of the world - I know — it sounds too good to be true - but a climate beneficial wardrobe is available. Those of us who care to investigate know that behind the attractively trendy brand tags and attractively low price tags of the global clothing industry lies a tangled web of exploitation and environmental destruction — not to mention 10% of global carbon emissions. The 2013 Rana Plaza disaster that killed over a thousand garment factory workers in Bangladesh awakened many of us to the high (human and ecological) cost of “fast fashion.”

The good news is that the movement to create a more ethical apparel industry is gaining momentum, and there are lots of ways to be a part of it. But there’s more. What if we could have clothing be not only more ethical, not only “less bad” for the environment, but in fact beneficial in terms of climate?

It is happening. Fibershed, the California non-profit developing regional and regenerative fiber systems, is now certifying fiber farmers who grow Climate-Beneficial™ Wool and — for the first time this year — rolling out regionally raised and produced textile made of such wool.

We are so excited about sharing some of our first bolts of climate beneficial, community cloth for the designers and brands that always bring further artistry to the fabric's life. Working alongside our local and regional partners as we grow our micro-mill infrastructure will be a journey, with much to learn and advance from upstream and downstream specialties. Gaining ground on climate resiliency one fabric – connected to community – at a time.

*Featured image from XYZ, Photographer credit -

"The Collaboratory was designed to propel inventive and tangible solutions that address the most important social and environmental challenges facing the apparel industry today," said Michael Kobori, Vice President of Sustainability at LS&Co. "We’re energized by the collective talent of this diverse group of leaders – and excited to see how they push boundaries to address the climate impact of the apparel industry."

We’re excited to announce the 12 leaders who have been selected as the second class of fellows in the Levi Strauss & Co. Collaboratory; a program for socially and environmentally responsible entrepreneurs in the apparel industry to collaborate on sustainability solutions. It’s also part of LS&Co.’s continued effort to making an outsized impact by working with like-minded partners committed to sustainable progress.

This year’s class of Collaboratory fellows will focus on climate change and reducing the apparel industry’s climate impact. Each individual brings exceptional creativity to their work, along with proven passion for advancing sustainable innovation and business practices.

The 2018 LS&Co. Collaboratory fellows are:

Read More at Levi Strauss

The start to our journey in finding a 1960's X3 Draper shuttle loom in need of some TLC - come join us in this exciting Draper salvage story that was community driven, producing a range of products over the past few years we want to catalogue and give truths to.

When we first came upon the idea of 'industrializing' our equipment, we knew Draper shuttle looms, of varying width had to be on our dream list. To find, restore, and maintain - has been a journey for the ages and continues to modern day operations.

Loom Specs and Dimensions

Reed collections for these traditional

Spare parts are tricky to come by, especially when they aren't manufactured anymore, nor are there any modern day supports. Through generous community wisdom on operating these machines, and lots of hours in heritage manuals, we've engineered ways through many technical challenges with these machines. To find spare parts - a bit like classic car collecting - find parts from here, there and sometimes manufacture it yourself.