The Huston Crafted Series brings you a little closer to the world of textile design and making as we highlight the hidden details that go into producing our collection of premium cloth, running the creative gamut from knits to woven goods. At Huston, we restore and empower a heritage of fiber craft through a truly artisan American textile making experience. In this first edition of the series, we look through a few of our favorite custom denim projects, and some of the process it takes to create at our domestic mill. Lets dive in at our denim fabric and process favorites – our 12oz Double Slub, a 14oz Botanical Indigo and a 10oz Natural denim – lets explore !

Denim Weaving Process -

As a denim is brought to life, the design process of material selection and machinery selection is paramount. When we consider a denim project on our looms – these are the key points to consider for a beautiful product without too much waste.

– Raw Material, Warp and weft yarn specifications including TPI (twist per inch), size, color, weight, end pattern and strength/application characteristics. Once we have a sample yarn and prototyped construction of a test swatch (before larger productions), we can further tweak the variables.

Raw Materials and Designing an End Denim Product from the Field

Cotton comes in many shapes, sizes and colors! A variety of cotton genetics are grown domestically, from California to West Texas, and beyond. We continually work with our coalition partners in third party domestic fields of expertise – from regional farmers to upstream manufacturing facilities – to produce fine domestic products, and processes for our products with our supply chain partners.

What is Denim?

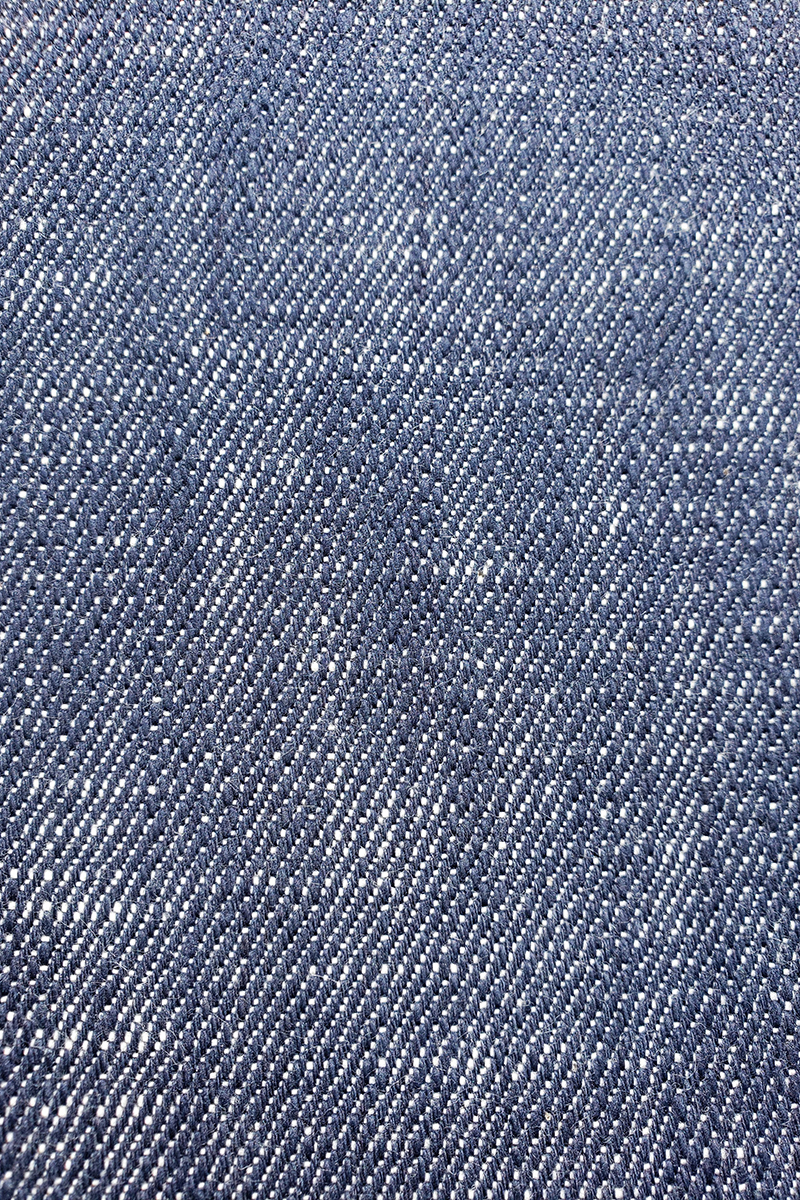

Denim is a sturdy cotton warp-faced textile in which the weft passes under two or more warp threads. This twill weaving produces a diagonal ribbing that distinguishes it from canvas, and often makes it a stronger construction for utilitarian toughness. The main difference between denim and canvas is the weave construction. Canvas is made with a simple plain weave pattern of “over one, under one”. (*Using two yarns in the over under instead of one, but it is still a plain weave, is often referred to as ‘double fill’).

Characteristics of denim Twill fabrics are made by going over one yarn and under two yarns or even under three yarns. The weave is shifted over in each row creating a diagonal line in the pattern. The diagonal line makes a twill easy to identify

Denim is available in a range of colors, but the most common denim is indigo denim in which the warp thread is dyed while the weft thread is left white. As a result of the warp-faced twill weaving, one side of the textile is dominated by the blue warp threads and the other side is dominated by the white weft threads. Modern day denims fabricated from this cloth are thus predominantly white on the inside.

Body PIC-denim yarns/color and setup to machine convos ahead

Our historical denims are made on traditional shuttle looms which typically produces a bolt about 35 inches (760 mm) wide. We do have several size looms to accommodate up to 58’ finished widths.

Body PIC ; MACHINE/S most used in our denim’s weaving stage shown (Draper X3/XD)

Body VID : MACHINE/S most used in our denim’s weaving stage shown (Draper X3/XD)

SELVAGE or selvedge came from ‘SELF-EDGE’ is also referred to as ‘Redline.’ Selvage is the narrow tightly woven band on either edge of the denim fabric, parallel to the warp. A selvage end prevents the edge of the denim from unraveling. In some fabrics selvages are closed, whereas on larger modern weaving machines, the weft yarn is cut on every pick, creating what is called a ‘fringe’ selvage.

Although not always the case, shuttle-loom-woven denim is typically recognizable by density, and by its selvedge, the edge of a fabric created as a continuous cross-yarn (the weft) reverses direction at the edge side of the shuttle loom. The selvedge is traditionally accentuated with warp threads of one or more contrasting colors, which can serve as an identifying mark.

Body PIC - Selvedge – ticker ids (even if on Chambray/canvas, next to each other to show differencens

Although quality denim can be made on many looms, selvedge denim has come to be associated with premium products since final production that showcases the selvedge demands artisan care, and price points.

Denim fabric thickness can vary with a yard of fabric weighing anywhere from 9 to 32 oz, with 9 to 14 oz being typical range used in consumer apparel and accessory goods. Our looms are capable of heavy denims, however not ‘bull denims’ which usually push past 15oz fabric weight constructions and require more specialized machinery.

Woven Materials Displayed include :

FABRIC – 100% American-Made Botanical Indigo Denim

SOURCING – American upland cotton, yarn spun and skein dyed in North Carolina

PROCESS – A super soft, long-lasting denim fabric made from 100% ring spun cotton; woven on our vintage Draper X3 loom

DYES – 100% botanically dyed organic cotton warp, natural organic cotton weft

DETAILS – Weight: 14oz | Width: 33" | Right Hand 3/1 Twill

FABRIC – 100% American-Made Double Slub Selvedge Denim

SOURCING – American upland cotton sourced from West Texas, yarn spun and dyed in North Carolina

PROCESS – A super long-lasting and soft slub denim made from 100% ring spun cotton; woven on our vintage Draper X3 loom

DYES – Blue sulfur dyed slub warp for a mineral dye quality that stays richer longer, with natural slub weft

DETAILS – Weight 12oz | Width: 28" | Right Hand 3/1 Twill

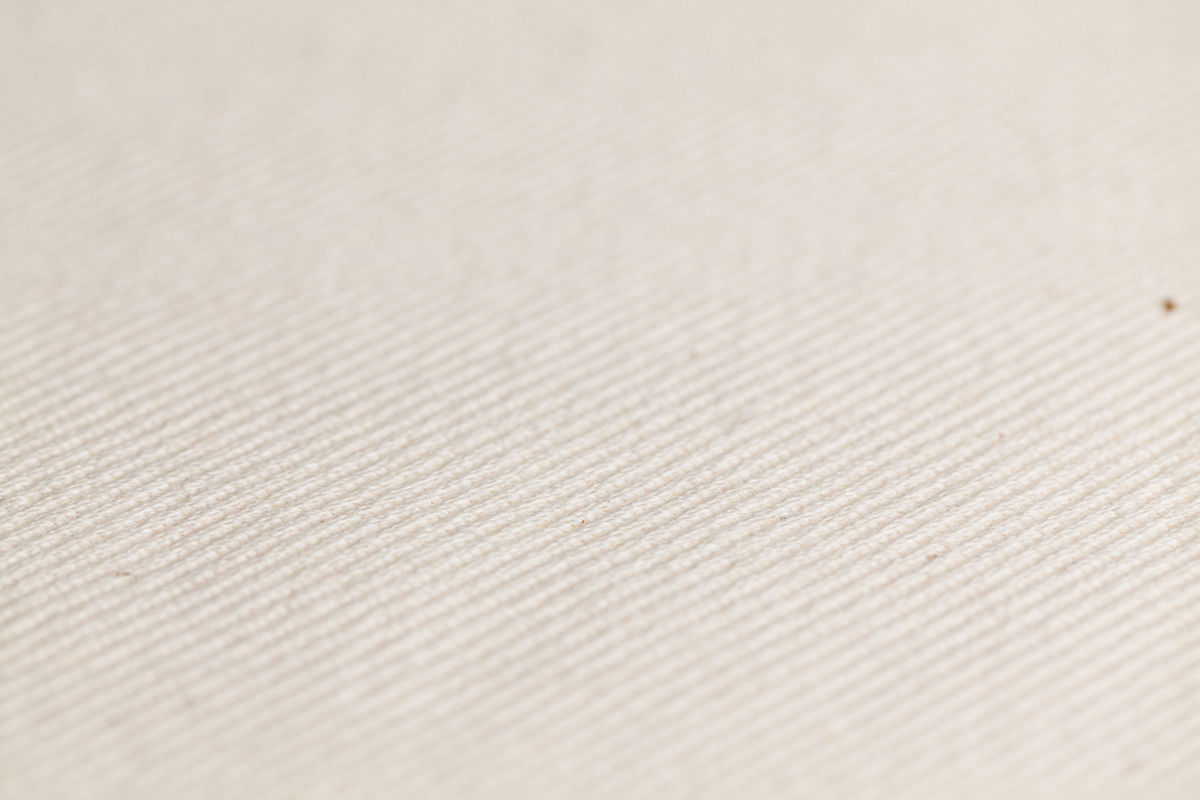

FABRIC – 100% American-Made Natural Denim

SOURCING – American West Texas Organic cotton sourced, yarn spun and dyed in North Carolina

PROCESS – A pairing of natural organic cotton weft with a natural organic cotton warp; woven on our vintage Draper X3 loom

DYES – Natural warp and natural weft

DETAILS – Weight: 10oz | Width: 45" | Left Hand 3/1 Twill

If you’re looking for a little inspiration or simply want to expand your fabric knowledge, check back often as we are adding expanding content monthly. We’d also love to hear your feedback with what you’d like us to produce and share next – please send us an email or give us a call to talk about your project!

(Featured in VOGUE MAGAZINE)

By Emily Farra - Septemeber 1st, 2021

Regenerative Agriculture Comes to the Luxury Market with Co's California-Grown, American-Made Capsule

Fans of Stephanie Danan and Justin Kern’s luxurious, minimalist label Co have Paul Hawken to thank for their next purchase. The husband-and-wife duo had a chance encounter with the author, Erewhon founder, and Project Drawdown organizer in 2019 and raised a pressing question: How should a brand of Co’s size be addressing its impact?

“We had been bumping into a lot of walls,” Kern explains. “With all the information out there between packaging, shipping, and materials, our concern was what would actually be meaningful.” Hawken brought up regenerative agriculture and explained its particular appeal in California. From vegetables to livestock to cotton, regenerative farming practices—which are essentially a step beyond organic, with extra attention paid to biodiversity and soil health—can replenish the land and eventually draw down more carbon into the soil. That’s where Hawken’s Project Drawdown gets its name: Their top-line goal is to reduce the 109 billion tons of carbon that’s trapped in the atmosphere and contributing to the earth’s rapid warming.

“We’re in such a grave place right now, it didn’t feel like enough to ‘contribute’ by just buying deadstock fabrics or using leftovers from last season,” Danan says. The aim behind Co’s new collection, titled Natural World, wasn’t simply to reduce the brand’s impact, but to play an active role in repairing the earth by harnessing regenerative ag. The couple worked with Rebecca Burgess of Fibershed to create a new supply chain from scratch, and spent the last year-and-a-half driving up and down their home state to meet with farmers and herders—a distinct pivot from their usual fabric trips to Italy and France.

The results debuted on Co’s website earlier this week: raw-edged blouses, drawstring trousers, lofty cardigans, fine-gauge knits, and coccoon coats in un-dyed, certified Climate Beneficial Wool (Fibershed’s seal of approval for regeneratively farmed materials). Other labels have experimented with regenerative fibers of late, among them Eileen Fisher, Christy Dawn, and Allbirds. But Co’s capsule, titled Natural World, is one of the first examples in the high-end luxury space. “And that’s where it should be,” Danan says. “Luxury is a lifestyle, and wearing something that has this kind of impact is a luxurious experience.”

“It just feels good,” Kern adds. “Shouldn’t that be the point of luxury? I think we’ve lost that, and luxury has just become about a logo or a price. We’ve forgotten that a luxury good is something where the utmost care is taken at every step, from the soil to the way the animal is treated to the mill... At the end, it isn’t a surprise that it’s a really luxurious product.”

The quality might be the big takeaway for Co’s designer peers. If conversations around farming, soil health, and crop rotation sound a little, well, earthy, the end product is undeniably luxe. “It’s like no other wool I’ve ever felt,” Kern says. Danan described the texture as pleasantly “spongy”—and with none of the itch we expect from standard wool.

The duo consider the project a “laboratory,” one that can help them understand how to eventually transition their entire collection into regenerative materials. They’re also hoping to make a bigger statement about local production: “California is America’s largest agriculture source, and it’s something fashion has completely overlooked,” Kern says. “It’s a huge opportunity to not just make things in the U.S., but to grow the materials here, too. The more support these farms can get from American designers and brands, the more they can invest in regenerative practices.”

The same goes for their Sacramento textile mill, Huston Textiles, the last remaining maker of selvage fabrics in the U.S. Its founder Ryan Huston is credited prominently on Co’s website, along with their wool rancher, Ryan Mahoney, and Burgess. The hope is that other designers will contact them to work on similar fashion projects. “This is only going to work if everyone gets involved,” Kern adds.

Their debut Natural World capsule is rounded out by a few pieces in ultra-soft recycled cashmere and organic linen, reflecting the brand’s broader commitment to natural, organic, and repurposed materials. Kern and Danan are eager to introduce regenerative cotton, cashmere, and other fibers in the future. “When you’re working nonstop, season after season, it’s easy to get bogged down and forget why you’re doing this,” Kern says. “But this has really made us excited about making clothes again.”

Imagine if you wore clothing that had a beneficial impact of the world - I know — it sounds too good to be true - but a climate beneficial wardrobe is available. Those of us who care to investigate know that behind the attractively trendy brand tags and attractively low price tags of the global clothing industry lies a tangled web of exploitation and environmental destruction — not to mention 10% of global carbon emissions. The 2013 Rana Plaza disaster that killed over a thousand garment factory workers in Bangladesh awakened many of us to the high (human and ecological) cost of “fast fashion.”

The good news is that the movement to create a more ethical apparel industry is gaining momentum, and there are lots of ways to be a part of it. But there’s more. What if we could have clothing be not only more ethical, not only “less bad” for the environment, but in fact beneficial in terms of climate?

It is happening. Fibershed, the California non-profit developing regional and regenerative fiber systems, is now certifying fiber farmers who grow Climate-Beneficial™ Wool and — for the first time this year — rolling out regionally raised and produced textile made of such wool.

We are so excited about sharing some of our first bolts of climate beneficial, community cloth for the designers and brands that always bring further artistry to the fabric's life. Working alongside our local and regional partners as we grow our micro-mill infrastructure will be a journey, with much to learn and advance from upstream and downstream specialties. Gaining ground on climate resiliency one fabric – connected to community – at a time.

*Featured image from XYZ, Photographer credit -

"The Collaboratory was designed to propel inventive and tangible solutions that address the most important social and environmental challenges facing the apparel industry today," said Michael Kobori, Vice President of Sustainability at LS&Co. "We’re energized by the collective talent of this diverse group of leaders – and excited to see how they push boundaries to address the climate impact of the apparel industry."

We’re excited to announce the 12 leaders who have been selected as the second class of fellows in the Levi Strauss & Co. Collaboratory; a program for socially and environmentally responsible entrepreneurs in the apparel industry to collaborate on sustainability solutions. It’s also part of LS&Co.’s continued effort to making an outsized impact by working with like-minded partners committed to sustainable progress.

This year’s class of Collaboratory fellows will focus on climate change and reducing the apparel industry’s climate impact. Each individual brings exceptional creativity to their work, along with proven passion for advancing sustainable innovation and business practices.

The 2018 LS&Co. Collaboratory fellows are:

Read More at Levi Strauss

The start to our journey in finding a 1960's X3 Draper shuttle loom in need of some TLC - come join us in this exciting Draper salvage story that was community driven, producing a range of products over the past few years we want to catalogue and give truths to.

When we first came upon the idea of 'industrializing' our equipment, we knew Draper shuttle looms, of varying width had to be on our dream list. To find, restore, and maintain - has been a journey for the ages and continues to modern day operations.

Loom Specs and Dimensions

Reed collections for these traditional

Spare parts are tricky to come by, especially when they aren't manufactured anymore, nor are there any modern day supports. Through generous community wisdom on operating these machines, and lots of hours in heritage manuals, we've engineered ways through many technical challenges with these machines. To find spare parts - a bit like classic car collecting - find parts from here, there and sometimes manufacture it yourself.