The Huston Crafted Series brings you a little closer to the world of textile design and making as we highlight the hidden details that go into producing our collection of premium cloth, running the creative gamut from knits to woven goods. At Huston, we restore and empower a heritage of fiber craft through a truly artisan American textile making experience. In this first edition of the series, we look through a few of our favorite custom denim projects, and some of the process it takes to create at our domestic mill. Lets dive in at our denim fabric and process favorites – our 12oz Double Slub, a 14oz Botanical Indigo and a 10oz Natural denim – lets explore !

Denim Weaving Process -

As a denim is brought to life, the design process of material selection and machinery selection is paramount. When we consider a denim project on our looms – these are the key points to consider for a beautiful product without too much waste.

– Raw Material, Warp and weft yarn specifications including TPI (twist per inch), size, color, weight, end pattern and strength/application characteristics. Once we have a sample yarn and prototyped construction of a test swatch (before larger productions), we can further tweak the variables.

Raw Materials and Designing an End Denim Product from the Field

Cotton comes in many shapes, sizes and colors! A variety of cotton genetics are grown domestically, from California to West Texas, and beyond. We continually work with our coalition partners in third party domestic fields of expertise – from regional farmers to upstream manufacturing facilities – to produce fine domestic products, and processes for our products with our supply chain partners.

What is Denim?

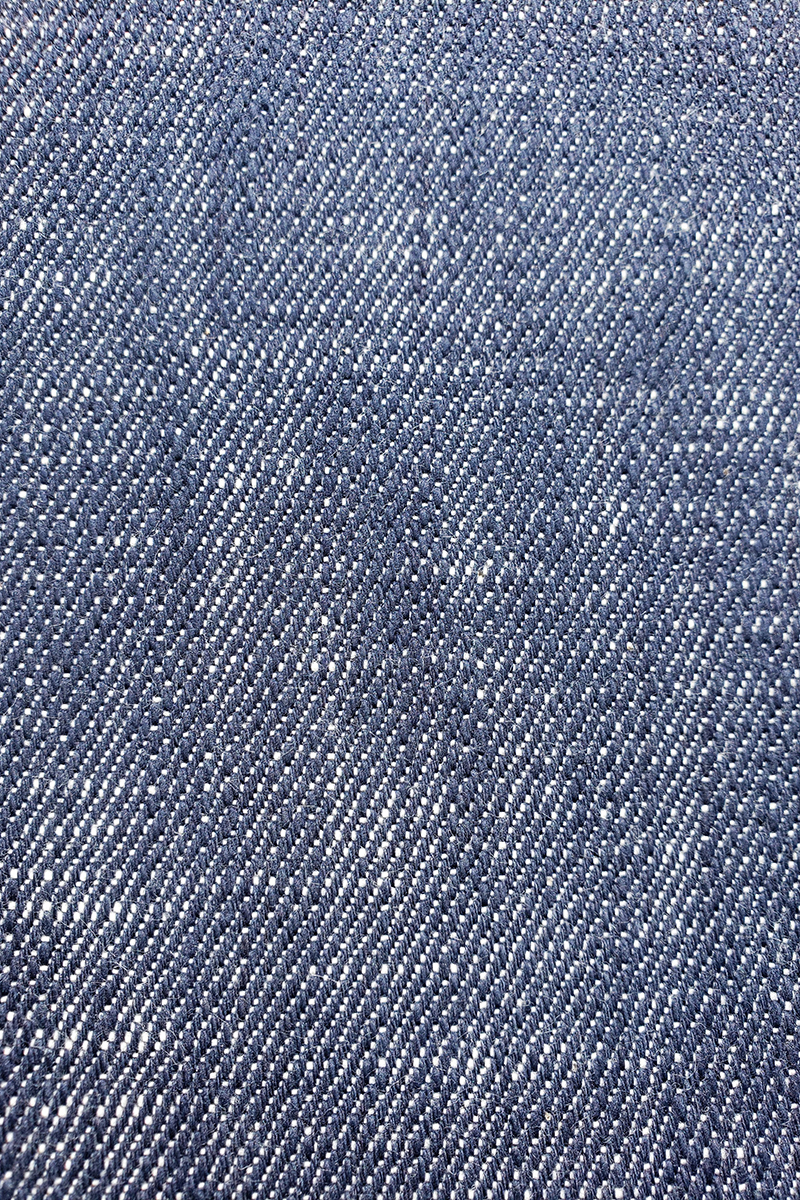

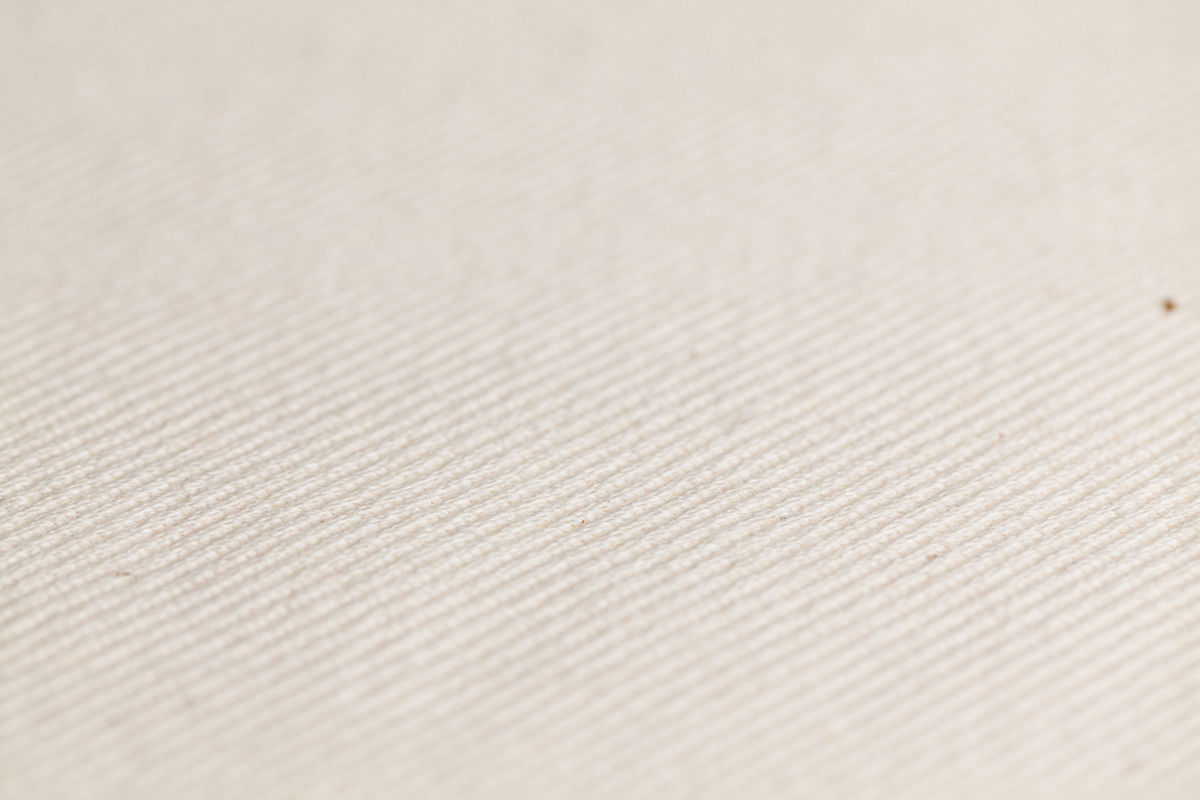

Denim is a sturdy cotton warp-faced textile in which the weft passes under two or more warp threads. This twill weaving produces a diagonal ribbing that distinguishes it from canvas, and often makes it a stronger construction for utilitarian toughness. The main difference between denim and canvas is the weave construction. Canvas is made with a simple plain weave pattern of “over one, under one”. (*Using two yarns in the over under instead of one, but it is still a plain weave, is often referred to as ‘double fill’).

Characteristics of denim Twill fabrics are made by going over one yarn and under two yarns or even under three yarns. The weave is shifted over in each row creating a diagonal line in the pattern. The diagonal line makes a twill easy to identify

Denim is available in a range of colors, but the most common denim is indigo denim in which the warp thread is dyed while the weft thread is left white. As a result of the warp-faced twill weaving, one side of the textile is dominated by the blue warp threads and the other side is dominated by the white weft threads. Modern day denims fabricated from this cloth are thus predominantly white on the inside.

Body PIC-denim yarns/color and setup to machine convos ahead

Our historical denims are made on traditional shuttle looms which typically produces a bolt about 35 inches (760 mm) wide. We do have several size looms to accommodate up to 58’ finished widths.

Body PIC ; MACHINE/S most used in our denim’s weaving stage shown (Draper X3/XD)

Body VID : MACHINE/S most used in our denim’s weaving stage shown (Draper X3/XD)

SELVAGE or selvedge came from ‘SELF-EDGE’ is also referred to as ‘Redline.’ Selvage is the narrow tightly woven band on either edge of the denim fabric, parallel to the warp. A selvage end prevents the edge of the denim from unraveling. In some fabrics selvages are closed, whereas on larger modern weaving machines, the weft yarn is cut on every pick, creating what is called a ‘fringe’ selvage.

Although not always the case, shuttle-loom-woven denim is typically recognizable by density, and by its selvedge, the edge of a fabric created as a continuous cross-yarn (the weft) reverses direction at the edge side of the shuttle loom. The selvedge is traditionally accentuated with warp threads of one or more contrasting colors, which can serve as an identifying mark.

Body PIC - Selvedge – ticker ids (even if on Chambray/canvas, next to each other to show differencens

Although quality denim can be made on many looms, selvedge denim has come to be associated with premium products since final production that showcases the selvedge demands artisan care, and price points.

Denim fabric thickness can vary with a yard of fabric weighing anywhere from 9 to 32 oz, with 9 to 14 oz being typical range used in consumer apparel and accessory goods. Our looms are capable of heavy denims, however not ‘bull denims’ which usually push past 15oz fabric weight constructions and require more specialized machinery.

Woven Materials Displayed include :

FABRIC – 100% American-Made Botanical Indigo Denim

SOURCING – American upland cotton, yarn spun and skein dyed in North Carolina

PROCESS – A super soft, long-lasting denim fabric made from 100% ring spun cotton; woven on our vintage Draper X3 loom

DYES – 100% botanically dyed organic cotton warp, natural organic cotton weft

DETAILS – Weight: 14oz | Width: 33" | Right Hand 3/1 Twill

FABRIC – 100% American-Made Double Slub Selvedge Denim

SOURCING – American upland cotton sourced from West Texas, yarn spun and dyed in North Carolina

PROCESS – A super long-lasting and soft slub denim made from 100% ring spun cotton; woven on our vintage Draper X3 loom

DYES – Blue sulfur dyed slub warp for a mineral dye quality that stays richer longer, with natural slub weft

DETAILS – Weight 12oz | Width: 28" | Right Hand 3/1 Twill

FABRIC – 100% American-Made Natural Denim

SOURCING – American West Texas Organic cotton sourced, yarn spun and dyed in North Carolina

PROCESS – A pairing of natural organic cotton weft with a natural organic cotton warp; woven on our vintage Draper X3 loom

DYES – Natural warp and natural weft

DETAILS – Weight: 10oz | Width: 45" | Left Hand 3/1 Twill

If you’re looking for a little inspiration or simply want to expand your fabric knowledge, check back often as we are adding expanding content monthly. We’d also love to hear your feedback with what you’d like us to produce and share next – please send us an email or give us a call to talk about your project!